As the world moves towards a healthier lifestyle, many people are not only evolving their diets and daily habits but the way they operate their businesses. One of these people is David Reed of Houston, Texas, a former traditional builder who made the move to natural building after 27 years.

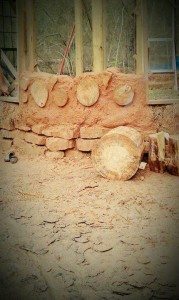

David is now the owner of Texas Natural Builders, a natural building group that specializes in earthen homes as well as reclaimed and repurposed material structures. TNB uses locally sourced materials and plan salvage operations to save valuable materials from ending up in landfills. David also teaches workshops and skillshares on natural building with a focus on cob structures.

We caught up with David to find out more about natural building, cob, and why he left traditional building.

What is cob?

Cob is a Welsh word meaning lump or loaf. In natural building, Cob is it the name given to the mixture of clay, sand and straw.

How did you get into Cob building?

I have been a conventional home builder for 27 years. I wanted to provide a more connected life for my children so I began searching for better, less impactful methods of home building and stumbled into natural building.

In 27 years of conventional building I did build 2 log cabin homes in New Mexico that helped me start walking the path of healthy non toxic home building, created with materials sourced from the build site as much as possible, as well as repurposed materials from demolished structures.

What are the positives and negatives of working with cob?

Cob has several benefits. First, you have thermal mass. Thermal mass is the ability of a material to absorb and store heat energy. A lot of heat energy is required to change the temperature of high density materials like concrete, bricks and tiles. They are therefore said to have high thermal mass. Lightweight materials such as timber have low thermal mass. Cob takes a long time to rise in temperature, keeping a relatively cool temperature inside the structure.

There are also the benefits of sound proofing, sculptable beauty, extremely local material sourcing, and the ability to change and augment shapes at a moments decision.

One of the down sides to cob is (there are no negative if you think about it) the labor it takes to build a cob home. Its very labor intensive and requires many hands (and feet!) to accomplish a build in a somewhat rapid pace.

What roadblocks are there to building a cob structure within an urban environment versus a rural one?

Most urban environments are structured around a monetized building system economy, meaning that everything that goes into building a conventional home pads MANY pockets along the way. From the designer to the architect to permitting to storm management to planning to approved material to tradesman to aesthetics to material yards to pretty much any facet of the building economy. This is a huge hindrance.

Sure you can do it in the country but it removes you from what a city provides until that sprawl finally reaches you in the country….

What has been the biggest lesson you have learned in your experience with natural building?

I would say that my biggest lesson was no matter how poisonous conventional materials are, no matter how crappy conventional homes are built, and no matter how much money is thrown away to fit it into the cookie cutter system – people will still turn up their noses to Natural Homes. Even with their extremely affordable, healthy, extremely well-built and crafty methods used, if it doesn’t fit into the cookie cutter mold, the majority will reject it.